Others

Rise of Indian Steel Sector

From PLI Scheme to Technological Advancement, Key Reforms in Steel Industry

Posted On:

13 AUG 2024 3:07PM

Introduction

The steel sector is essential to vital industries including construction, infrastructure, automotive, engineering, and defence. In recent years, the steel industry has witnessed remarkable growth, with India rising to become a major global player in steel production. Today, India stands as the world’s second-largest producer of steel. This growth underscores the country's significant role in shaping global steel markets and supporting industrial advancements worldwide.

Record Steel Manufacturing

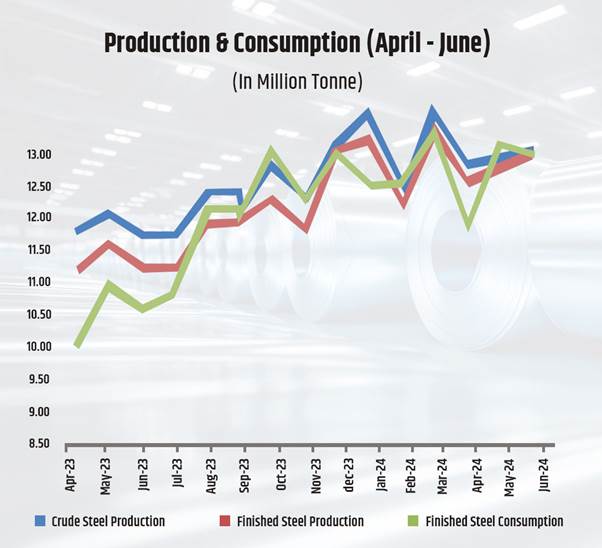

The performance of the steel sector during April-June FY ’25 (Q1:FY25) has surpassed the levels for this period in any fiscal year. In the first quarter of FY25, crude steel production reached 36.61 million tonnes (MT), finished steel production clocked 35.77 MT, and finished steel consumption hit 35.42 MT. [1]

These figures exceed those from the corresponding periods over the past four years, as illustrated in the accompanying graph of production and consumption trends.

Notably, Month-by-Month (M-o-M) data shows an overall upward trend in both crude and finished steel production, as well as in finished steel consumption.

Although there are M-o-M fluctuations, the general trajectory indicates strong and consistent growth in the sector. This performance highlights the sector's robust recovery and expansion, positioning it for continued success in the coming quarters.

In June 2024, Crude steel production increased by 0.3 % from 12.22 million tonnes in May 2024 to 12.26 million tonnes in June 2024.

Finished steel production increased by 1.2 % from 11.92 million tonnes in May to 12.06 million tonnes in June. Further, the consumption of steel decreased by 1.0 % from 12.13 million tonnes in May ’24 to 12.01 million tonnes in June ’24.[2]

Rise in Domestic Steel Demand

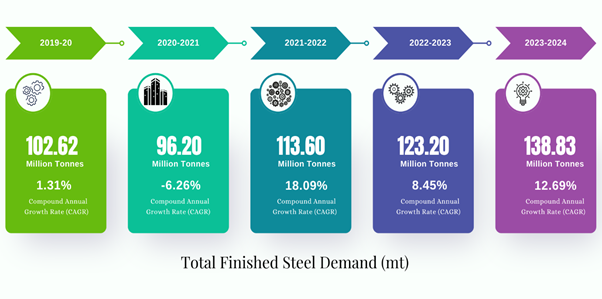

There has been an uptrend in domestic steel demand. Data on the demand for total finished steel in India during the last five financial years indicates a Compound Annual Growth Rate (CAGR) of 6.51%.[3]

Key Government Reforms in the Steel Sector

To foster a supportive policy environment for the steel sector and advance the 'Make in India' initiative, the Government of India has taken several key measures over the years.

- Domestically Manufactured Iron & Steel Products (DMI&SP) Policy: This policy promotes the use of domestically produced steel in government procurement, supporting the growth of local manufacturing.

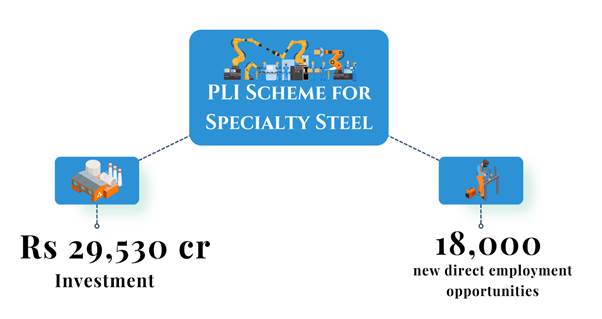

- Production Linked Incentive (PLI) Scheme for Specialty Steel: The Government has launched this scheme to stimulate the production of specialty steel within India. The PLI Scheme aims to reduce imports by attracting significant capital investment.

Under the Production Linked Incentive (PLI) Scheme, five broad categories of specialty steel have been identified:

1. Coated/Plated Steel Products

2. High Strength/Wear Resistant Steel

3. Specialty Rails

4. Alloy Steel Products and Steel Wires

5. Electrical Steel

Further, companies selected under the PLI Scheme for Specialty Steel have committed to an additional investment of approximately Rs 29,530 crores. By the end of the scheme’s tenure, these investments are expected to generate around 18,000 new direct employment opportunities.[4]

- Process-Based Safety Guidelines: On July 25, 2024, the Ministry of Steel introduced 16 new safety guidelines designed to enhance productivity by standardizing safe operational practices within the steel industry.

- Revamped Steel Import Monitoring System (SIMS): SIMS has been upgraded to SIMS 2.0 as of July 25, 2024. This enhanced system is intended to more effectively monitor steel imports and address concerns affecting the domestic steel industry.

- Notification of Steel Scrap Recycling Policy: The Government has announced the Steel Scrap Recycling Policy aimed at increasing the availability of domestically generated scrap. This policy is designed to boost the recycling of steel scrap within the country, thereby enhancing the sustainability of the steel sector and reducing reliance on imported scrap.

- PM Gati-Shakti National Master Plan: The "Make in India" initiative, supported by the PM Gati-Shakti National Master Plan, will intensify engagement with key sectors—including Railways, Defence, Petroleum and Natural Gas, Housing, Civil Aviation, Road Transport and Highways, Agriculture, and Rural Development. The goal is to boost steel usage, increase overall demand, and attract investment in the steel industry

- Strategic Coordination Between Ministries and States: Optimizing the availability of raw materials for steel production by coordinating efforts with ministries, state governments, and other countries to obtain more favorable conditions.

- Ensuring Steel Quality Standards: The introduction of 145 Steel Quality Control Orders will prevent the manufacturing and import of non-standardized steel. This initiative is designed to make high-quality steel products more accessible to the public and uphold industry standards

Technological Advancements in Steel Industry

The steel industry operates in a deregulated environment, where companies independently decide on modernization and technological upgrades based on commercial factors and market dynamics. These companies are adopting the Best Available Technologies (BAT) globally as part of their modernization and technological advancement efforts.

To support environmental sustainability and reduce carbon emissions in the steel manufacturing sector, the following policies and initiatives are in place:

- R&D: The "Promotion of Research & Development in Iron & Steel Sector" scheme provides financial support to stakeholders for initiatives aimed at promoting environmental sustainability and reducing carbon emissions.

- National Green Hydrogen Mission: Launched by the Ministry of New and Renewable Energy (MNRE), this mission focuses on green hydrogen production and its application across various sectors, including steel. Under this mission, MNRE has introduced the "Implementation of Pilot Projects for Use of Hydrogen in the Steel Sector," developed in consultation with the Ministry of Steel.

- Steel Scrap Recycling Policy, 2019: This policy promotes the recycling of domestically generated steel scrap. By enhancing scrap availability, the policy helps reduce coal consumption in steelmaking and lowers emissions.

- Motor Vehicles Scrapping Rules (September 2021): These rules aim to increase the availability of scrap for the steel sector by facilitating the establishment of vehicle scrapping facilities.

- Perform, Achieve and Trade (PAT) Scheme: Part of the National Mission for Enhanced Energy Efficiency, the PAT scheme incentivizes the steel industry to reduce energy consumption.

Way Forward

Over the years, the steel sector has experienced remarkable growth, marked by substantial increases in both production and consumption. Per capita consumption of steel has risen from 59 kg in 2013-14 to 119 kg in 2022-23. In 2023, India produced 140.2 million tonnes of steel, positioning itself as the world's second-largest steel producer.

Looking ahead, the National Steel Policy (NSP) projects significant expansion in the sector. By the year 2030-31, India is expected to achieve a total crude steel capacity of 300 million tonnes, with crude steel production reaching 255 million tonnes and finished steel production at 230 million tonnes. This growth trajectory highlights the steel sector's crucial role in supporting the country's infrastructure and economic development.

References:

Click here to see PDF.

*****

Santosh Kumar/ Sarla Meena/ Abhinandan Sharma

(Explainer ID: 152018)

आगंतुक पटल : 11384

Provide suggestions / comments