Ministry of Electronics & IT

Government of India approves first batch of seven projects with investment of over ₹5500 crores under Electronics Manufacturing Component Scheme

Projects to Generate Production Worth ₹36,559 Crore and Create Over 5,100 Direct Jobs; Approved Units Spread Across Tamil Nadu, Andhra Pradesh and Madhya Pradesh

New Electronics Manufacturing Units to Meet 100% of Copper Clad Laminate, 20% of Printed Circuit Boards (PCB) and 15% of Camera Module Demand Domestically; 60% of Production to Be Exported: Ashwini Vaishnaw

India Makes Strong Entry into Component Materials Manufacturing; Projects to Reduce Import Dependence, Create High-Skill Jobs and Build Trusted Supply Chains for Defence, Telecom, EVs and Renewable Energy

Posted On:

27 OCT 2025 5:25PM by PIB Delhi

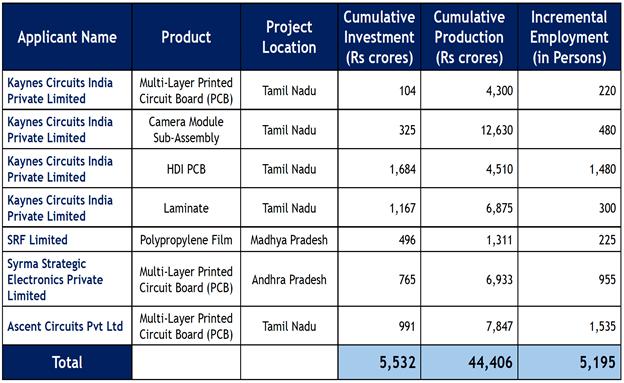

Union Electronics and IT Minister Sh. Ashwini Vaishnaw announced the approval of first trench of 7 projects under the Electronics Components Manufacturing Scheme (ECMS). Now Multi-Layer Printed Circuit Boards (PCBs) , HDI PCBs, Camera Modules, Copper Clad Laminates, and Polypropylene Films will be Made in India.

The move marks a major step in India’s journey from making finished products to manufacturing modules, components, materials & machineries used to manufacture them.

Overwhelming response for ECMS

The scheme has received wonderful response from both domestic and global companies. 249 applications have been recieved. These represents ₹1.15 lakh crore investment, ₹10.34 lakh crore production, and 1.42 lakh jobs to be created. It is the highest-ever investment commitment in India’s electronics sector.

Today marks the approval for seven projects worth ₹5,532 crore. These projects will lead to production of components worth ₹36,559 crore and creation of over 5,100 direct jobs.

The approved units are spread across Tamil Nadu (5), Andhra Pradesh (1), and Madhya Pradesh (1). This reinforces the balanced regional growth and expanding high-tech manufacturing beyond metros.

Bridging the Demand–Supply Gap

Union Minister Sh. Ashwini Vaihnaw informed, "20% of our domestic demand of PCBs and 15% of Camera Module sub-assembly will be met through production from these plants."

He also mentioned that the demand of copper clad Laminate will now completely be domestically met. The additional 60% of production through these plants will be exported.

Product details

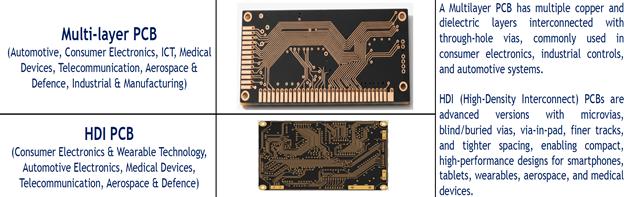

The approved projects cover key components like High-Density Interconnect (HDI) PCBs, Multi-Layer PCBs, Camera Modules, Copper Clad Laminates, and Polypropylene Films.

Camera modules are compact imaging units that capture photos and videos in electronic devices. Its production in India will enable its usage in smartphones, drones, laptops, tablets, medical instruments, robots, and automotive systems.

HDI and Multi-Layer PCBs are the core circuit boards that connect and control every electronic device. These are used in smartphones, laptops, automotive and industrial systems.

Strategic Breakthroughs in Base Materials

ECMS also marks India’s strong entry into component materials manufacturing.

For the first time, India will establish a Copper Clad Laminate (CCL) manufacturing facility. CCL acts as a base component for manufacturing Multi-layer PCBs. These PCBs go into every electronic equipment. Right now it is imported.

The Polypropylene Films is the key material used in manufacturing capacitors. This component will be made in India for Consumer Electronics, Automotive, ICT, Industrial & Manufacturing, Telecommunications & Computing equipments.

Economic and Industrial Impact

-

These projects will reduce import dependence and and lower product prices in the domestic market

-

These projects will create high-skill jobs in manufacturing and R&D

-

Trusted supply chains will be built for defence, telecom, EVs, and renewable energy

India is on its journey towards becoming a product nation, capable of designing, manufacturing, and exporting end-to-end electronic equipment. The scheme complements PLI and the India Semiconductor Mission (ISM).

It completes the seamless value chain, from devices to chips, components to materials, and from manufacturing to innovation.

***

Dharmendra Tewari\ Navin Sreejith

(Release ID: 2182986)

Visitor Counter : 17072