Ministry of Electronics & IT

Make in India’s Leap in Electronics Manufacturing & Exports

Driving Innovation & Growth

Posted On:

26 MAR 2025 1:46PM by PIB Delhi

- India: Second Largest Mobile Phone Producer in the World

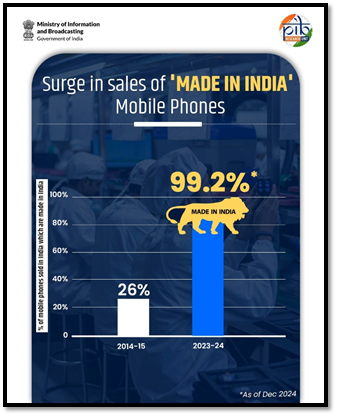

- In 2014-15, 26% of mobile phones sold in India were locally made, rising to 99.2% by December 2024

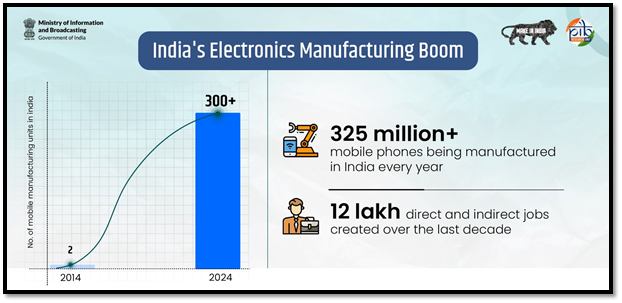

- In 2014, India had just 2 mobile manufacturing units; today, it has over 300

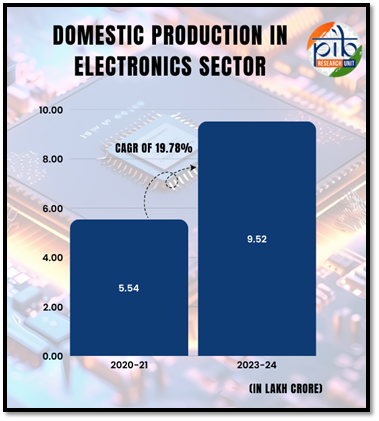

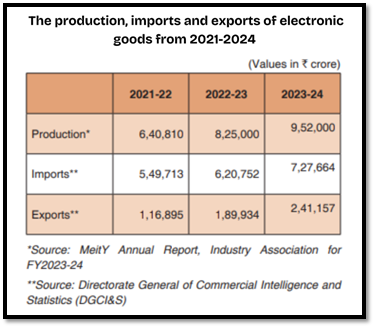

- Projections indicate that India’s electronics production will reach USD 300 billion by 2026

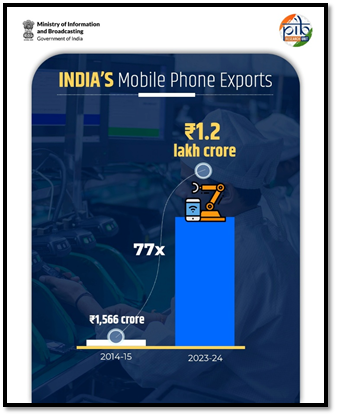

- India's mobile phone exports surged from ₹1,566 crore in 2014-15 to ₹1.2 lakh crore in 2023-24, marking a 77-fold increase

- India's semiconductor ecosystem has gained significant momentum, with five landmark projects receiving approval with a total combined investment nearing Rs 1.52 lakh crores

Introduction

Not long ago, India relied heavily on imports, with most electronics being imported. However, things are changing fast. With the Make in India initiative, the country is now building its own electronics industry, attracting big investments and boosting local production. As a result, India’s electronics exports are growing rapidly, even surpassing some traditional sectors like textiles. With strong government support and expanding factories, India is well on its way to becoming a global hub for electronics manufacturing.

[1]Projections indicate that India’s electronics production will reach USD 300 billion by 2026.

Government schemes for the Electronics boom in India

Make in India

Launched in 2014, the Make in India initiative has been a pivotal step in India's nation-building efforts. The initiative was conceived during a period when India's economic growth had sharply declined, and the country faced critical challenges in sustaining its development trajectory. Against this backdrop, "Make in India" was designed to transform India into a global hub for design and manufacturing. Its core objectives were to facilitate investment, encourage innovation, and develop world-class infrastructure. As one of the pioneering 'Vocal for Local' initiatives, it sought not only to boost India's manufacturing capabilities but also to showcase its industrial potential on a global stage.[2]

The "Make in India" initiative has been a cornerstone in transforming India into a global manufacturing hub. With a strong focus on enhancing industrial capabilities, fostering innovation, and creating world-class infrastructure, the initiative aims to position India as a key player in the global economy.

Smartphones in India:

- India has made significant progress in mobile and electronics manufacturing and become the world’s 2nd largest mobile manufacturing country. In 2014, India had only 2 mobile manufacturing units but fast forward to today, the nation boasts over 300 manufacturing units, underscoring a significant expansion in this vital sector.

- In 2014 -15 only 26% of the mobile phones which were being sold in India were made in India, the rest were being imported. It is worth mentioning that today, 99.2% of all mobile phones which are sold in India are made in India.

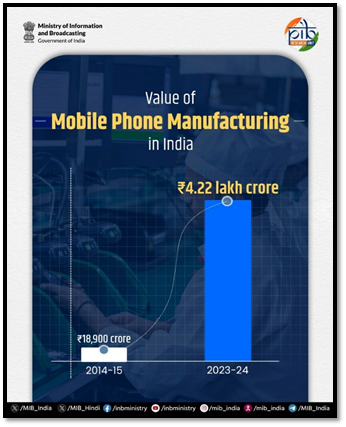

- The manufacturing value of mobile phones has surged from ₹18,900 crore in FY14 to a staggering ₹4,22,000 crore in FY24.

- More than 325 to 330 million mobile phones a year are being manufactured in India and on average there are about a billion mobile phones in use in India.

- The exports, which were almost non-existent in 2014, have now surpassed ₹1,29,000 crore.[3]

As a result, India’s electronics sector is experiencing significant growth supported by various government initiatives meant to position the country as a global leader.[4]

[5]

[5]

An overview of mobile phone manufacturing in India and its success

[6]

[6]

Phased Manufacturing Programme (PMP)

The Phased Manufacturing Programme (PMP) has been notified to promote domestic value addition in mobile phones and their sub-assemblies/parts manufacturing in 2017. This scheme aims to encourage large-scale production and create a strong local manufacturing ecosystem for mobile devices. As a result, India has rapidly started attracting investments into this sector and significant manufacturing capacities have been set up in the country. The manufacturing of mobile phones has been steadily moving from Semi Knocked Down (SKD) to Completely Knocked Down (CKD) level, thereby progressively increasing the domestic value addition. [7] Semi Knocked Down (SKD) refers to a product partially assembled before shipping, while Completely Knocked Down (CKD) means a product is shipped as individual components for final assembly at the destination.

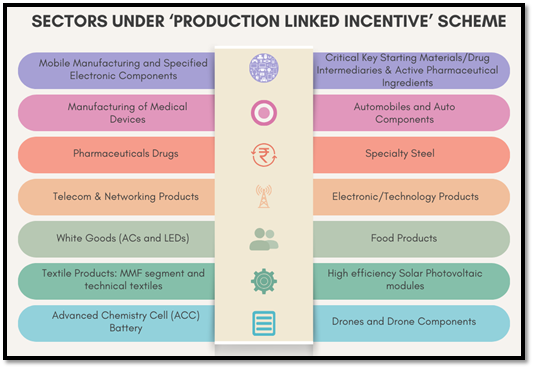

Production linked Incentive (PLI) Schemes

To boost domestic manufacturing and attract investment in mobile phones value chain including electronic components and semiconductor packaging, Production Linked Incentive Scheme (PLI) for Large Scale Electronics Manufacturing was notified on April 1, 2020. The scheme extends an incentive of 3% to 6% on incremental sales (over base year) of goods manufactured in India and covered under target segments viz. Mobile Phones and Specified Electronic Components, to eligible companies, for a period of 5 years.[8]

In a strong push to accelerate industrial growth, the Government has significantly increased budget allocations for key sectors under the PLI Scheme, reaffirming its commitment to strengthening domestic manufacturing. The allocation for Electronics soared from ₹5,747 crore (revised estimate for 2024-25) to ₹8,885 crore in 2025-26. [9]

As of February 2025, the scheme has led to:

- Cumulative investment of INR 10,905 Cr

- Cumulative production of INR 7,15,823 Cr

- Cumulative exports of INR 3,90,387 Cr

- Generated additional employment of 1,39,670 (direct jobs)[10]

(for Large Scale Electronics Manufacturing)

The primary goals of the PLI Schemes are to attract substantial investments, incorporate advanced technology, and ensure operational efficiency. By fostering economies of scale and enhancing global competitiveness, these schemes are expected to significantly boost production, stimulate manufacturing activities, and contribute to economic growth over the coming years.[11]

Semiconductor Ecosystem Development - India's semiconductor market to grow at 13%, reach Rs. 8,95,134 crore (US$ 103.4 billion) by 2030: IESA (India Electronics and Semiconductor Association)[12]

Semicon India Program:

Launched in 2021 with a financial outlay of ₹76,000 crore, the Semicon India program is structured to promote the domestic semiconductor industry through incentives and strategic partnerships. This initiative supports various sectors of the semiconductor industry, extending beyond just fabrication facilities (fabs) to include packaging, display wires, Outsourced Semiconductor Assembly and Testing (OSATs), sensors, and other critical components, creating a comprehensive ecosystem.[13]

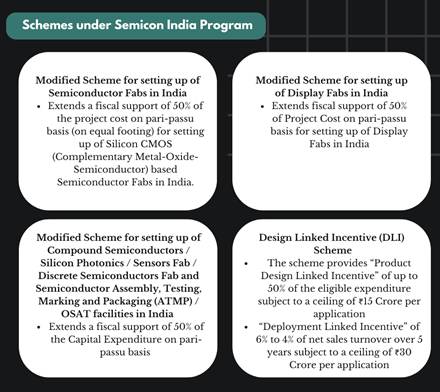

Following four schemes have been introduced under the aforesaid programme:

.[14]

.[14]

At Global Investors Summit 2025, it was announced that India’s first indigenous semiconductor chip will be ready for production by 2025.[15]

India's semiconductor ecosystem has gained significant momentum, with several landmark projects receiving approval-

- The first major project with Micron was sanctioned for nearly Rs 22,000 crores.[16]

- Tata Electronics Private Limited (TEPL)’s proposal for setting up a Semiconductor Fab facility in India with an investment of ₹91,526 Crore was approved in February 2024. The fab facility will be set up in a technology partnership with PSMC, Taiwan. PSMC is an established semiconductor company having 6 semiconductor foundries in Taiwan. The production capacity of the project would be around 50,000 wafer starts per month (WSPM).

- Tata Electronics Private Limited (TEPL)’s proposal for setting up of OSAT facility in India with an investment of ₹27,120 Crore was approved in February 2024. The facility will use indigenous semiconductor packaging technologies with a production capacity of 48 million per day.

- CG Power and Industrial Solutions Limited’s proposal for setting up an OSAT facility in India with an investment of ₹7,584 Crore was also approved in February 2024. The facility will be set up as a joint venture partnership with Renesas Electronics America Inc., USA, and STARS Microelectronic, Thailand. The Technology would be provided for this facility by Renesas Electronics Corporation, Japan and STARS Microelectronic, Thailand. The production capacity would be around 15.07 million Units per day.

- Kaynes Technology India Limited (KTIL) proposal for setting up of Outsourced Semiconductor Assembly and Test (OSAT) facility at Sanand, Gujarat for Wire bond Interconnect, Substrate Based Packages was approved in September, 2024. The Technology would be provided by ISO Technology Sdn. Bhd. and Aptos Technology Inc. This facility will be set up with an investment of ₹3,307 Crore. The facility will have the capacity to produce more than 6.33 million chips per day.[17]

These proposals have a total combined investment nearing Rs 1.52 lakh crores, signalling a strong commitment to advancing India's position in the global semiconductor landscape. [18] Setting up a semiconductor manufacturing base in the country has been a significant part of Make in India, which India has been attempting to achieve for over six decades.

The Scheme for Promotion of Manufacturing of Electronic Components and Semiconductors (SPECS) helps mitigate the challenges of domestic manufacturing of electronic components and semiconductors in order to strengthen the electronics manufacturing ecosystem in the country. The scheme will provide financial incentive of 25% on capital expenditure for the identified list of electronic goods that comprise downstream value chain of electronic products, i.e., electronic components, semiconductor/ display fabrication units, ATMP units, specialized sub-assemblies and capital goods for manufacture of aforesaid goods, all of which involve high value added manufacturing.[19]

India Semiconductor Mission, Tata Electronics, and Tata Semiconductor Manufacturing Sign Fiscal Support Agreement for Semiconductor Fab – In March 2025, in a significant milestone for India's semiconductor industry, India Semiconductor Mission (ISM), Tata Electronics Private Limited (TEPL), and Tata Semiconductor Manufacturing Private Limited (TSMPL) have signed a Fiscal Support Agreement (FSA) for India's first commercial semiconductor fab in Dholera, Gujarat. This breakthrough agreement represents a decisive step forward in strengthening India's technological self-reliance under the modified programme for semiconductor & display manufacturing ecosystem in India.[20]

Conclusion:

India's rapid transformation into a global electronics manufacturing hub is a testament to the success of the Make in India initiative. With numerous schemes to support the manufacturing processes in India, the country has significantly boosted local manufacturing, exports, and investment. The remarkable growth from just 2 mobile manufacturing units in 2014 to over 300 today, demonstrates India's commitment to self-reliance and innovation. As India moves towards a USD 300 billion electronics production target by 2026, its robust policies and skilled workforce are paving the way for sustained growth, positioning the nation as a key player in the global electronics and semiconductor industry.

References-

Make in India’s Leap in Electronics Manufacturing & Exports

****

Santosh Kumar/ Ritu Kataria/ Kritika Rane

(Release ID: 2115171)

Visitor Counter : 12902