Farmer's Welfare

Food Irradiation: Strengthening India’s Cold Chain for Safer, Longer-Lasting Food

Posted On:

02 DEC 2025 2:11PM

- Ministry of Food Processing Industries financially supports setting up of multiproduct food irradiation units under the scheme- Integrated Cold Chain & Value Addition Infrastructure (Cold Chain scheme) of PMKSY

- The government approved ₹1,000 crore outlay in July 2025, including funding for 50 new food irradiation units nationwide.

- As of June 2025, 395 integrated cold chain projects have been approved under the Cold Chain Scheme. Of these, 291 projects are operational, creating a preservation capacity of 25.52 LMT.

- As of August 2025, 16 project proposals have been approved for setting up of multi-product food irradiation units, of which 9 are operational

|

Introduction

What are Processed Foods?

Processed foods are those that have been altered from their natural state before consumption through methods such as heating, pasteurization, canning, drying, freezing, or refrigeration. Nearly all foods available in markets undergo some degree of processing of raw materials into products to enhance safety, extend shelf life, improve nutritional value, and freshness for consumers

|

Food processing has progressed over millions of years, from the earliest use of fire for roasting food to traditional techniques like pickling, fermenting, freezing, and drying, and now to modern innovations such as 3D food printing. Today, Industrial food processing involves large-scale, technology-driven methods that convert raw materials into safe, stable, flavourful, and high-quality products. These processes often add value by extending shelf life and enhancing marketability.

Furthermore, food processing is a science-driven field that aims to ensure safer, more nutritious, and convenient food for consumers. Techniques such as pasteurization, sterilization, drying, freezing, and irradiation help eliminate harmful microorganisms, reduce spoilage, and greatly prolong shelf life. By preserving surplus harvests, processing also minimises food waste. Methods like fermentation, germination, and fortification enhance nutritional value, while specialised processing enables the creation of products such as lactose-free milk and gluten-free flours. Additionally, food processing strengthens agri-food value chains, contributes to economic development, and ensures the availability of diverse, affordable, and safe foods for consumers.

What is Food Irradiation?

Exposing fruits to a controlled dose of ionising radiation that kills bacteria, mould, and insects, and extends shelf life without making the fruit ‘radioactive’ or unsafe.

|

Among the various methods of food processing, food irradiation has emerged as an important technique due to its strong scientific validation and proven safety record. Foods processed by radiation have undergone thorough assessment in national and international laboratories, with studies showing no toxicological, nutritional, or microbiological issues. Its safety has also been endorsed by several reputed scientific bodies and associations, including the American Medical Association, the American Gastroenterological Association, the American Dietetic Association, and the Institute of Food Technologists.

In India, food irradiation is used to preserve and process commodities such as potatoes, onions, spices, mangoes, cereals, pulses, and oilseeds. This technique offers several benefits, including:

a. Preventing sprouting in potatoes, onions, and other tubers

b. Increasing the shelf life of fruits and vegetables

c. Eliminating insect infestations

d. Reducing microbial contamination

e. Fulfilling quarantine and export requirements

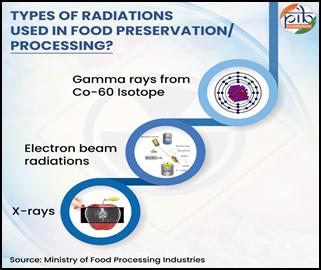

In food irradiation, three types of radiation sources are used depending on the application:

- Gamma rays: Generated from radioactive forms of Cobalt-60. In India, the Board of Radiation and Isotope Technology (BRIT) under the Department of Atomic Energy supplies Cobalt-60 for food irradiation. An MoU or agreement with BRIT is a prerequisite for obtaining this source.

- X-rays: Produced by reflecting a high-energy stream of electrons off a target substance (usually one of the heavy metals) into food, are also commonly used in medicine and industry.

- Electron beams (e-beam): A stream of high-energy electrons from an accelerator directed onto food, provides rapid processing

Irradiation serves as one of the important tools for consumers to make informed decisions when buying packaged food items. Consumers should choose certified products by looking for the FSSAI license number, Organic or fortification logos (e.g., fortified with iron, vitamin D), Quality Certification (HACCP, ISO 22000, FSSC), and other certifications with logos like Agmark, BIS, Vegan, and Irradiated products.

In addition to certifications, consumers should carefully examine the nutrition label, focusing on per-serving values, including calories, fat, sugar, sodium, added sugars, saturated fats, fiber, and protein. Reviewing the ingredient list is equally important to identify hidden sugars, artificial additives, and other components. Consumers should also be cautious of marketing phrases like “low-fat,” “sugar-free,” “home-made,” or “natural,” as these terms can be misleading and do not necessarily reflect a healthy product.

Overall, food irradiation provides an additional, dependable layer of safety and quality assurance, helping ensure that food reaching consumers is fresher, cleaner, and has a longer shelf life. Moreover, government support is available for establishing irradiation infrastructure under the Integrated Cold Chain and Value Addition Infrastructure (ICCVAI) component.

Scheme Supporting Food Irradiation- ICCVAI

Ministry of Food Processing Industries (MoFPI) provides financial assistance for establishing multiproduct food irradiation facilities, which play a crucial role in reducing post-harvest losses and minimizing wastage of perishable agricultural produce by extending shelf life. This support is provided under the scheme- Integrated Cold Chain & Value Addition Infrastructure (Cold Chain scheme) of the Pradhan Mantri Kisan Sampada Yojana (PMKSY).

The scheme was launched to address the persistent challenge of post-harvest losses in India, particularly for highly perishable commodities such as fruits, vegetables, dairy, meat, poultry, and fish. Considerable losses occur throughout the supply chain, including harvesting and handling, transportation, storage, and processing, leading to reduced farmer incomes, increased consumer prices, and pressures on national food security. The primary objective of the scheme is to establish an uninterrupted cold chain network from the farm gate to retail outlets, thereby mitigating losses and enabling farmers to obtain improved economic returns.

Although the scheme was introduced earlier, it was restructured and incorporated under the PMKSY in the 2016-17 financial year. PMKSY serves as an umbrella programme of the MoFPI, aimed at developing modern food processing infrastructure with efficient supply chain linkages from production to retail. Within this framework, the cold chain scheme focuses on creating integrated, end-to-end cold chain systems that effectively connect farmers, processors, and markets. This integration helps reduce wastage, generate employment, and improve the overall competitiveness of the perishable goods sector.

|

How the Scheme (ICCVAI) Supports?

Grants-in-aid/Subsidy is provided @35% of eligible project cost for projects in General Areas and @50% of eligible project cost for projects in Difficult Areas as well as for projects of SC/ST, FPOs and SHGs, subject to the maximum of ₹10 crore per project.

Difficult Areas include North-Eastern States (including Sikkim), Uttarakhand, Himachal Pradesh, Jammu & Kashmir, Ladakh, Integrated Tribal Development Programme (ITDP) areas, and Islands.

ELIGIBILITY CRITERIA:

- Eligible entities include Individuals and organizations, such as FPOs, FPCs, SHGs, NGOs, PSUs, firms, and companies, etc.

- Minimum 1 acre of land is required for setting up of both standalone and integrated food irradiation unit.

LATEST NOTIFICATION:

Vide notification, dated, 27 May 2025, MOFPI has invited proposals from eligible entities from across the country under component scheme ICCVAI- setting up of multi product Food Irradiation Units. The entities are required to submit their proposals online at https://sampada-mofpi.gov.in/

|

Strategic Objectives of the Initiative

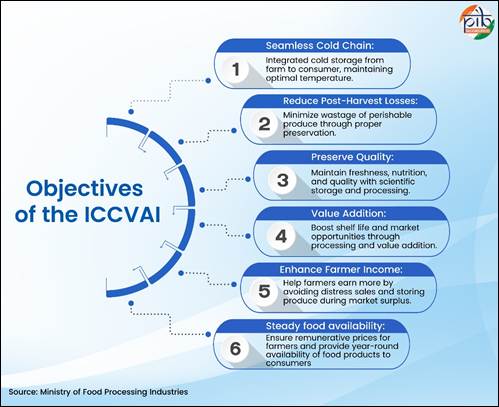

The core objectives of the ICCVAI (Integrated Cold Chain and Value Addition Infrastructure), an initiative of the Ministry of Food Processing Industries, focus on strengthening India’s food supply chain, improving quality, and enhancing farmer income. The initiative focuses on building an integrated cold chain from farm to consumer to maintain optimal temperatures and prevent spoilage, thereby reducing post-harvest losses. Through scientific storage and processing, it helps preserve freshness, nutrition, and overall quality.

The scheme also supports value addition to extend shelf life and create new market opportunities, ultimately boosting producer earnings. By enabling farmers to store surplus produce, it prevents distress sales and helps them obtain better prices. Additionally, it ensures fair returns for farmers and consistent, year-round availability of food products for consumers, strengthening the stability and efficiency of the entire food supply chain.

Major Components driving ICCVAI

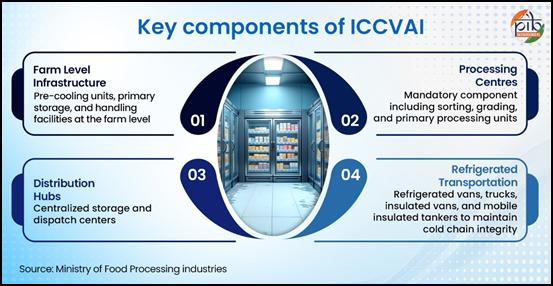

The scheme supports the development of facilities across the entire supply chain, with a strong emphasis on facilities at the farm level. To receive financial assistance under the general cold chain scheme, applicants must establish Farm Level Infrastructure (FLI) and ensure its linkage to a Distribution Hub (DH) and/or refrigerated or insulated transport.

Progress Overview and Milestones achieved

Expanded Financial Outlay: In July 2025, the government approved an additional outlay of ₹1,920 crore for the PMKSY, raising the total allocation to ₹6,520 crore for the 15th Finance Commission cycle (up to March 31, 2026). This approval includes ₹1,000 crore to support the setting up of:

- 50 Multi-Product Food Irradiation Units under Integrated Cold Chain and Value Addition Infrastructure (ICCVAI).

- 100 NABL-accredited Food Testing Labs (FTLs) under Food Safety and Quality Assurance Infrastructure (FSQAI).

This significant increase reflects the government’s strong commitment to expanding the impact of cold chain infrastructure. The proposed 50 multi-product food irradiation units are expected to create a total preservation capacity of 20-30 lakh Metric Tonnes (LMT) per annum, depending on the type of food products irradiated.

Progress of Cold Chain Projects: As of June 2025, a total of 395 integrated cold chain projects have been approved under the Cold Chain Scheme since its launch in 2008. Out of these, 291 projects have been completed and are operational, creating a preservation capacity of 25.52 lakh metric tonnes (LMT) per year and a processing capacity of 114.66 LMT per year. The completed and operationalised projects have generated 1,74,600 jobs across the country.

Substantial progress has been achieved since 2016–17. Since 2016-17, an amount of ₹1,535.63 crore has been released against approved grants-in-aid/subsidy of ₹2,066.33 crore for implementing 269 approved projects. During this period, 169 cold chain projects have been completed and operationalised across the country.

Status of Multi-Product Food Irradiation Units: As of August 2025, MoFPI has approved 16 project proposals for setting up of multi-product food irradiation units across the country. Out of these, 9 have been completed or are operational, while 7 are still under implementation. The total amount of Grants-in-aid of ₹112.99 Crore has been approved of which, ₹68.38 Crore has been released.

Conclusion

Food irradiation is emerging as a powerful solution to one of India’s biggest challenges, preserving the quality of perishable produce from farm to consumer. Enhancing safety, extending shelf life, and reducing post-harvest losses strengthens confidence for farmers, processors, and consumers. With increasing government support and expanding irradiation infrastructure, India is advancing towards a more resilient, modern, and efficient food ecosystem that delivers fresher, safer, and higher-quality food reaches every household.

References:

Ministry of Food Processing Industries

Food Safety and Standards Authority of India

Lok Sabha

Rajya Sabha

PIB Press Releases:

PIB Backgrounders:

Click here to see pdf

****

M

(Backgrounder ID: 156286)

आगंतुक पटल : 323

Provide suggestions / comments