Ministry of Science & Technology

Researchers develop recipe to predict crack emergence in clay, holds promise in improving quality of paints used for coatings

Posted On:

10 DEC 2024 5:17PM by PIB Delhi

Researchers have been able to accurately predict the exact time of the emergence of the first crack in aged clay. Their research is also applicable to other forms of drying colloidal layers like blood and paint—an information which could help in disease diagnosis, diagnosis of conditions like anemia by observing drying droplets of blood, forensics & painting restoration and improving the quality of paints used for coatings.

Clay, the major ingredient of natural soils, is used as a modifier while formulating paints and coatings. When subjected to desiccation, colloidal clay suspensions and clayey soils crack due to the accumulation of drying-induced stresses. Even when desiccation is suppressed, aqueous clay suspensions exhibit physical aging with their elasticity and viscosity evolving continuously over time as the clay particles self-assemble into gel-like networks due to time-dependent inter-particle screened electrostatic interactions.

Researchers studying material science at the Raman Research Institute (RRI), an autonomous institute of Department of Science and Technology (DST) have proposed a relation between the time of emergence of the first crack, fracture energy (which is the sum of the plastic dissipation and the stored surface energy) and the elasticity of the drying clay sample which can help predict the first crack.

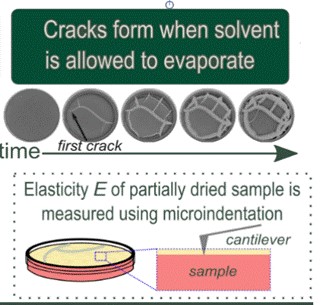

Using a theory called the theory of linear poroelasticity, they estimated the stress at the surface of the drying sample at the time of crack onset. Linear poroelasticity is a theory for porous media flow that describes the diffusion of water (or any mobile species) in the pores of a saturated elastic gel. They equated this stress with a critical stress predicted by a criterion that states that a crack will grow when the energy released during propagation is equal to or greater than the energy required to create a new crack surface (Griffith’s criterion).

The relation thus obtained was validated by performing a series of experiments. They further said that the same scaling relation worked for other colloidal materials such as silica gels. The paper was published in the journal Physics of Fluids.

“This correlation can be useful while optimizing material design during product development. We can apply this knowledge and suggest tweaking in the material composition at the time of manufacturing of industry-grade paints and coatings, so that they can have better crack resistance and improve the product quality,” said Professor Ranjini Bandyopadhyay, head of the RheoDLS lab and faculty at the Soft Condensed Matter group at RRI.

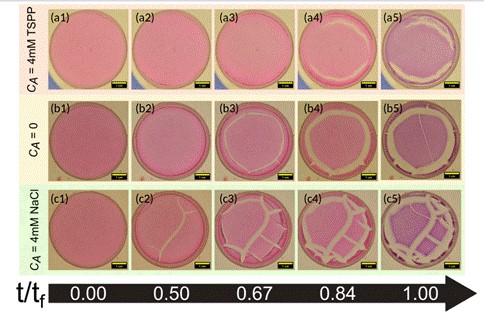

Using Laponite, a synthetic clay with disk-shaped particles sized 25 - 30 nanometres (nm) and one nm in thickness, the team created multiple Laponite samples with increasing elasticities. Each sample was dried at temperatures ranging from 35 to 50 degrees Celsius in a petri dish. The samples took between 18-24 hours to dry completely and the rate of evaporation and elasticity were measured for each sample. As water evaporated from the Laponite samples, the particles rearranged and stresses developed on the surface of the material.

Higher sample elasticity indicates better ability of the sample to deform under the influence of these stresses.

“The first crack emerged somewhere between 10 – 14 hours. Depending on the sample’s elasticity and fracture energy, the emergence time of the cracks varied. The crack onset time decreases with increasing temperature due to faster solvent loss, and therefore a more rapid enhancement in clay elasticity. The sample dries faster at higher temperature, enhancing the rate of stress development on its surface. Clay particles and their interactions influence the crack onset time because they govern the sample solidification rate and, therefore, mechanical properties, such as the fracture energy and elasticity,” said Vaibhav Parmar, the first author of the paper and a PhD student at RRI.

It was also noted that the cracks started developing first at the outer walls of the petri dish and later progressed inwards. Later, networks of cracks developed as the sample aged (passing of time).

The researchers said that crack formation in clay is a complex phenomenon observed over a range of length scales and hence, the need for understanding the drying-induced cracks was imperative. This information could help in better understanding of the geophysical and mechanical processes involved.

Clay is a highly heat-resistant material. It is an excellent insulator and hence they are the first choice for extreme heat environment applications, like coatings of a spacecraft. Researchers further said that a clay-water mixture would initially behave like a flowing liquid and over time it could turn into a viscoelastic solid, exhibiting properties of both liquid and solid. This study is significant as it tried to observe the effect of physical aging on the desiccation of clay.

“We could conclude that the more elastic the material, lower its fracture energy and faster the cracks developed. We have suggested a recipe for predicting crack formation in terms of the sample elasticity and fracture energy, which can be measured in laboratory experiments. Relations can be developed for cyclic temperature changes to mimic diurnal temperature fluctuations,” said Bandyopadhyay.

The research shows that by either varying the concentration of the material, the salt or the pH levels, it is possible to tune the material’s elasticity and in-turn, its cracking onset. This could be used to delay cracks in coatings on a spacecraft or on a medicine capsule which are done in a controlled environment.

Caption 1: Emergence of the first crack

Caption 2: Emergence of cracks with respect to time for samples a, b and c with varying elasticities

***

NKR/KS

(Release ID: 2082810)

Visitor Counter : 753