Ministry of Science & Technology

Composite membranes for detecting toxic amines can prevent disasters in industries

प्रविष्टि तिथि:

28 AUG 2024 5:47PM by PIB Delhi

A newly developed composite membranes made from two or more materials also called Mixed Matrix Membrane (MMM) showed remarkable color change when exposed to vapors of different amines, aiding in the detection of ammonia or other amine leaks in laboratories or industrial settings.

Ammonia or other aliphatic amines are extensively used as raw material or intermediate products in many chemical, fertilizer, and food industries. They are highly toxic and corrosive and become widely dispersed in the environment. They can quickly oxidize in water to produce several N-nitrosamines, which are very hazardous. Even direct contact with amines can cause severe respiratory irritation and skin burns. Occupational Safety and Health Administration (OSHA) has established a workplace threshold limit of 50 ppm for NH3. Concentrations above this level can lead to severe and potentially fatal health issues. Thus, detecting ammonia and aliphatic amines, whether in vapor or liquid form, at both high and low concentrations is essential for effective environmental and water monitoring and are extremely important for preventing onsite gas leakage and disasters.

Recently, 2D MOF nanosheets have attracted more attention than their 3D bulk counterparts. These 2D MOFs provide numerous exposed active sites, an extremely high surface-to-volume atomic ratio, and a larger specific surface area, which enhance their performance in various applications such as catalysis, gas separation, and storage.

Research team of Dr. Monika Singh at Institute of Nano Science and Technology (INST), Mohali, an autonomous Institute of Department of Science and Technology, synthesized a highly water-stable ultrathin Ni-btc nanosheets with a thickness of approximately 4.15 nm using the 2D oxide sacrifice approach (2dOSA). These MOF nanosheets exhibited exceptional sensitivity in detecting aliphatic amines and ammonia in an aqueous medium through a unique "turn-on" fluorescence process, which is rare.

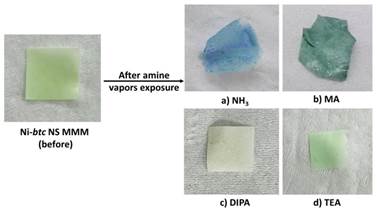

The researchers used these to fabricated a Mixed matrix membrane of MOF nanosheet that showed a naked-eye color change in the presence of NH3 and aliphatic amines. The response of color change differs in each case enabling MMMs to visually distinguish different types of amine vapors. These membranes are also reusable and can be easily employed for real-time detection of amines.

By using ultrathin MOF nanosheets to achieve a "turn-on" fluorescence response to ammonia and aliphatic amines in both aqueous and vapor phases, the research published in the journal Nanoscale opens new avenues for exploring nanomaterials in practical applications.

The MMM showed fabricated remarkable color change when exposed to vapors of different amines, aiding in the detection of ammonia or other amine leaks in laboratories or industrial settings, as they are extensively used as raw material or intermediate products in many chemical, fertilizer, and food industries. Therefore, designing 2D MOFs is essential for preventing major disasters by on-site gas leakage detection.

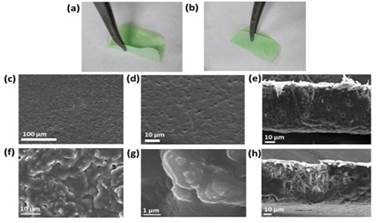

Figure. (a) and (b) Elucidating the flexibility of membrane; (c) and (d) FESEM images of the PVDF membrane indicating smooth surface; (e) FESEM image of the cross-section of PVDF membrane; (f) and (g) SEM images of Ni-btc NS MMM showing MOF NS embedded in membrane and (h) FESEM image of the cross-section of Ni-btc NS MMM.

***

KSY/PSM

(रिलीज़ आईडी: 2049440)

आगंतुक पटल : 1533